Buildings can be pretty boring. While their architecture may impress, the materials that make up houses, schools and skyscrapers mostly just sit around. But scientists are designing new building materials that respond to the environment and might even help improve it. One group has now developed a “living” concrete. Bacteria inside it help form the material and make more of it. In the process, this concrete sucks a greenhouse gas out of the air and stores it. That would be good for the environment.

The researchers reported their work in the February 5 Matter.

Concrete is made up of sand or rocks plus binders — such as cement — that hold the mixture together. Billions of cubic meters of concrete are produced every year. That makes it one of the most common building materials. But all of that concrete comes at an environmental cost. Making it releases a lot of carbon dioxide.

Carbon dioxide is a potent, heat-trapping greenhouse gas. Most people know that the burning of fossil fuels spews a lot of this gas. So does making cement, including that used in concrete. Cement accounts for more than one-twelfth of all carbon dioxide released into the air each year.

Bacteria help make the new concrete a different way. These microbes pull carbon dioxide out of the air and use it to grow. In the process, they make a mineral that helps toughen the new concrete, notes Wil Srubar. He is a materials scientist at the University of Colorado Boulder. He’s also part of the team that developed the concrete. The green-colored bacteria they use make for environmentally “greener” concrete, Srubar says.

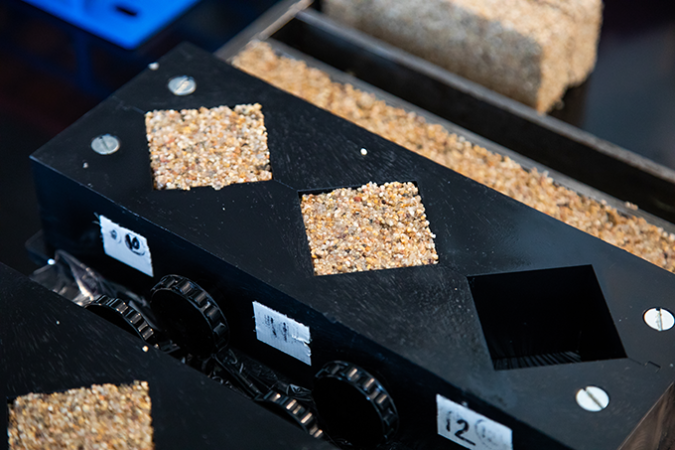

His team mixed the microbes together with sand and gelatin. Then they added nutrients, such as calcium. The researchers chose cyanobacteria (Sy-AN-oh-bak-TEER-ee-uh) for their microbes. These are like the bacteria or green algae that grow in a fish tank, Srubar explains. They thrive on carbon dioxide, using it and light to make the sugars that fuel their growth. That process is known as photosynthesis.

As they photosynthesize, the microbes suck carbon dioxide out of the air. So this process is “not releasing carbon. It’s storing carbon in the materials,” explains Anne Meyer. As a synthetic biologist, she engineers bacteria to make materials. She works at the University of Rochester in New York and was not involved with this study.

As the bacteria photosynthesize, they increase the pH of the mixture. This more basic environment causes little crystals of calcium carbonate to form. Calcium carbonate is an important ingredient in cement. Those bits make the new concrete tougher once it is shaped into bricks and cooled. Cooling the mixture also hardens the gelatin, similar to the process of making jiggly desserts in the kitchen.

Stayin’ alive

If the microbes can survive in the hardened concrete, Srubar’s team thought they might help make material for new bricks. To test the idea, they split a block and melted its pieces. They added more nutrients to the mix — and the bacteria grew. With additional sand, the mix had enough organisms to build two new concrete blocks.

The team then molded this mix into a new pair of blocks. By splitting, melting and growing three times, they made eight great-grandkid bricks from offspring of the original microbes. Since the growing bacteria help produce the material, this concrete could be made where it would be used, Srubar points out.

“It’s such a great approach,” says Meyer. “All of their techniques are so easy.” This could put the means of making building materials into the hands of non-experts, she says.

But this approach won’t put an end to regular concrete, at least not yet. “You have to be careful about contamination,” Meyer says. Srubar’s group worked in a lab where contamination is easy to avoid. In the real world, other microbes might get into the mix. If those microbes grow faster than the cyanobacteria, they could take over, she says. Those other microbes might prove harmful. Or they might change properties of the concrete. For instance, they might not help store carbon or grow to help make new materials.

These bacteria also need certain conditions to stay alive. They won’t survive well where it’s dry. Relative humidity is the amount of water vapor in the air (compared to how much it could hold). At 100 percent relative humidity, a lot of the concrete’s bacteria survived one month. But drop that humidity to 33 percent and they die “pretty dramatically after two weeks,” Meyer says.

She suspects that these microbes wouldn’t fare very well during the snowy, cold winters of her town of Rochester, N.Y. Such building materials may only work in places that are warm and humid all year.

When buildings come alive

For now, these are big limitations. That’s why Sarah Glaven suspects that “living building materials are not going to replace our existing building materials anytime soon.” Glaven is a biologist at the Naval Research Laboratory in Washington, D.C., and was not involved in this study.

Still, she is excited about how biology might someday play a role in engineering our buildings. Already “bacteria are everywhere and all over everything,” Glaven notes. “If we make them happy, then they may help to repair our materials or reuse those materials.” By growing new block materials from older blocks they’d melted, the researchers demonstrated how a living concrete might be recycled.

Microbes may even give materials properties that we can’t give them in other ways, she adds. Take self-healing, for example. When we get a cut, our skin regrows. “If you have materials that are alive, they can do the same thing,” Glaven says.

Living materials also could interact with people in new ways. Srubar envisions microbe-laced building materials that give off a scent. They might perfume the air by releasing small molecules that smell like a whiff of strawberries, perhaps. Or they might reveal if there’s too much carbon dioxide in the air by changing color. They might even share secret messages, he suggests, by giving off colored light under a specific light source.

“Nature has figured out a lot of really cool things that we can use in our day-to-day lives,” Srubar says. “We just have to pay a little more attention.”

This is one in a series presenting news on technology and innovation, made possible with generous support from the Lemelson Foundation.

"gas" - Google News

May 06, 2020 at 05:30PM

https://ift.tt/3cbqNDx

This ‘living’ concrete slurps up a greenhouse gas - Science News for Students

"gas" - Google News

https://ift.tt/2LxAFvS

https://ift.tt/3fcD5NP

Bagikan Berita Ini

0 Response to "This ‘living’ concrete slurps up a greenhouse gas - Science News for Students"

Post a Comment